RIVER PUSHER

River pusher

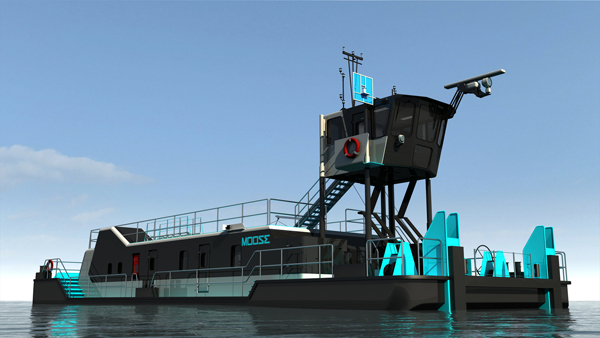

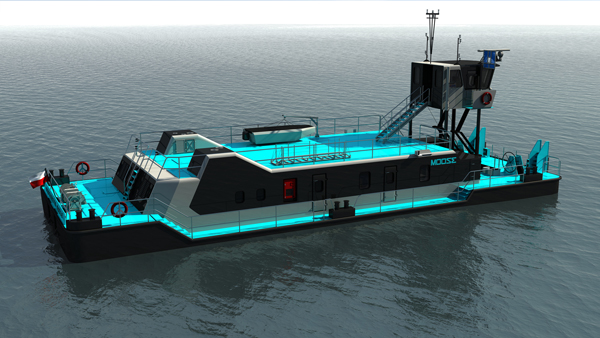

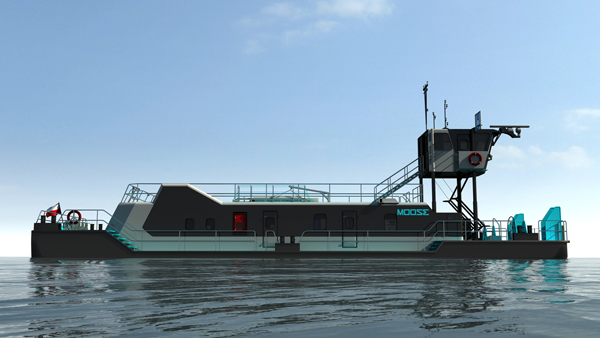

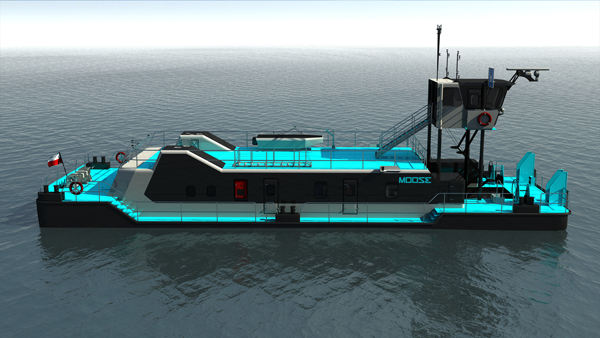

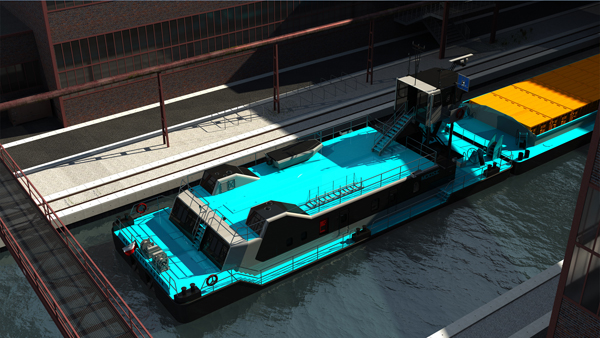

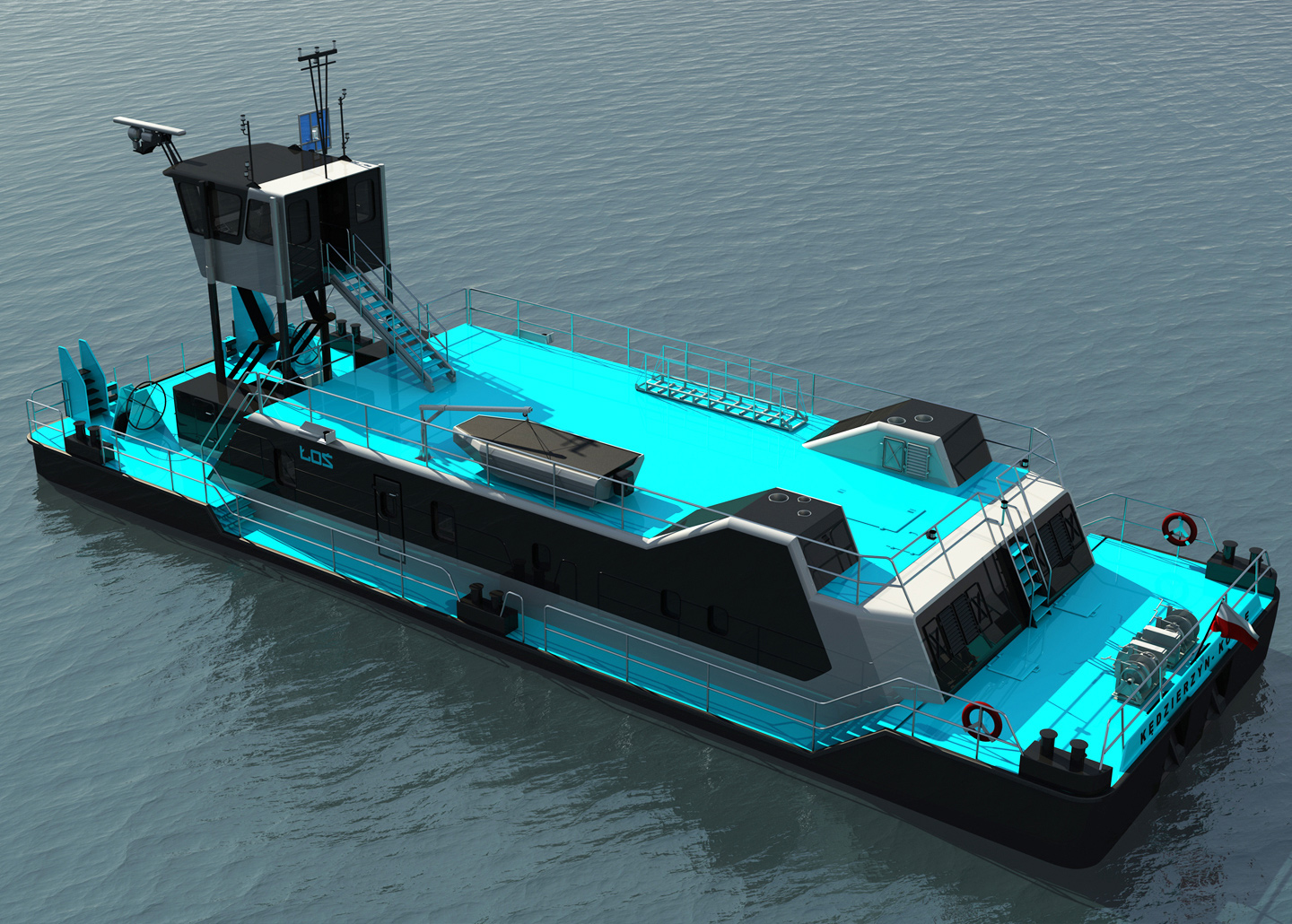

Model R&D works supporting the development of a prototype of an innovative inland waterway pusher as a response to shipping problems related to the current inland waterways. Project implemented in cooperation with Navishipproject for Koźle Shipyard as part of EU funding (POIR.01.02.00-00-0102 / 19). The idea of producing a pusher was born in response to the needs of companies interested in inland transport of bulky goods.

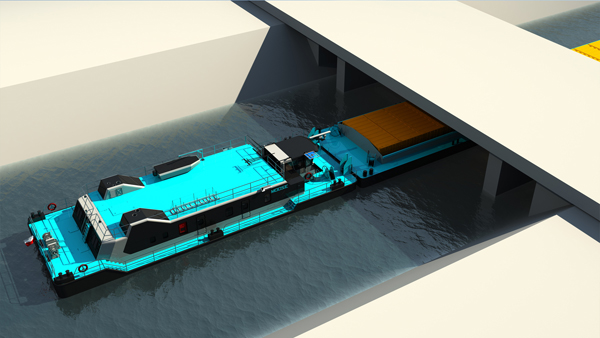

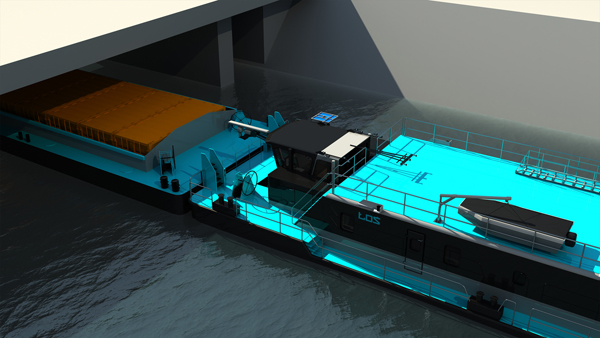

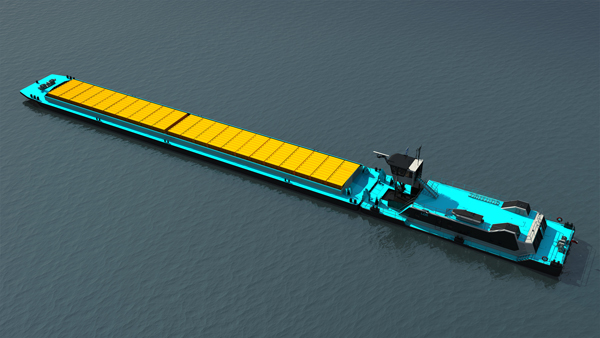

The main goal of the project is to verify and confirm the concept according to which it is possible to use a low draft pusher in the transport of loads. The pusher's task will be to ensure that the transport is carried out with the minimum water levels. The pusher is to be made as a flat-bottomed - three-bolt vessel - with a ballasting system, which in combination is not available in this type of vessel available on the market.

The next industrial research will mainly concern the design, analysis, modeling and laboratory experiments as well as the presentation and testing of the prototype in operational conditions. At the development stage, the pusher prototype will be presented and tested in real conditions. After obtaining a positive effect of the work, Stocznia Koźle will take steps to implement the technology of building a new generation of pushers.

The main goal of the project is to verify and confirm the concept according to which it is possible to use a low draft pusher in the transport of loads. The pusher's task will be to ensure that the transport is carried out with the minimum water levels. The pusher is to be made as a flat-bottomed - three-bolt vessel - with a ballasting system, which in combination is not available in this type of vessel available on the market.

The next industrial research will mainly concern the design, analysis, modeling and laboratory experiments as well as the presentation and testing of the prototype in operational conditions. At the development stage, the pusher prototype will be presented and tested in real conditions. After obtaining a positive effect of the work, Stocznia Koźle will take steps to implement the technology of building a new generation of pushers.

DETAILS

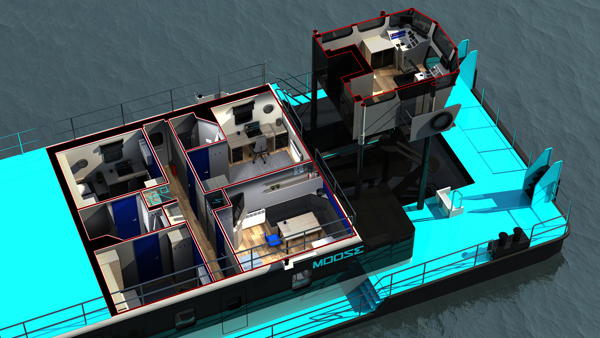

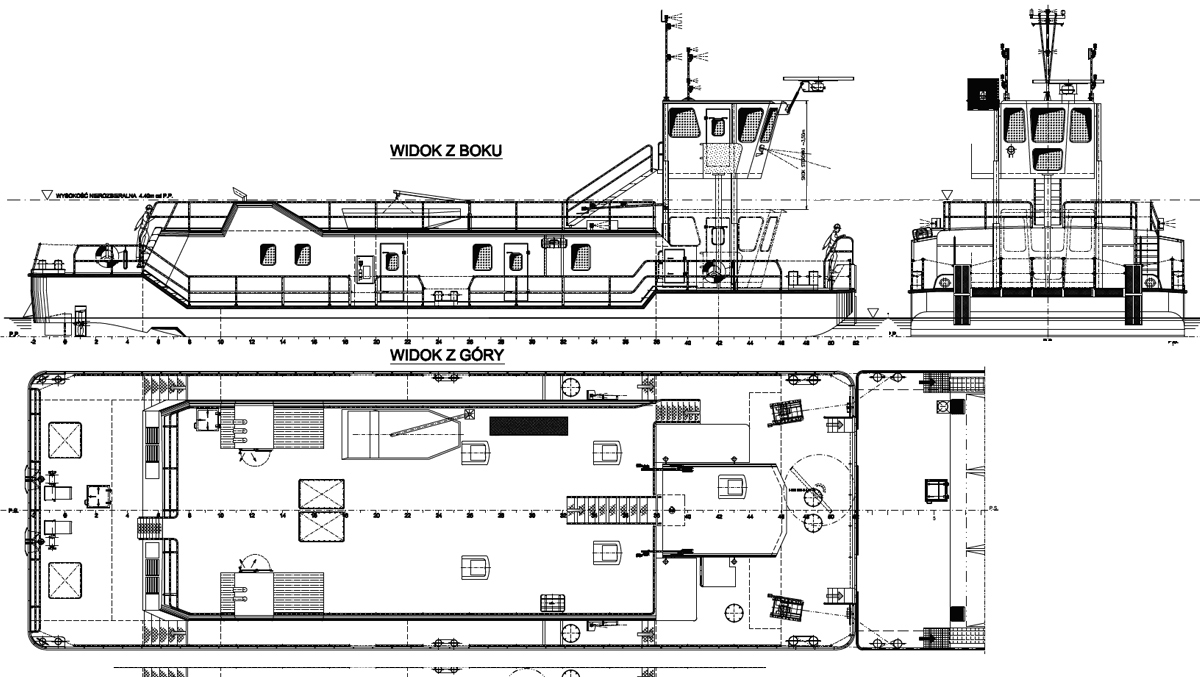

INTERIOR PLAN

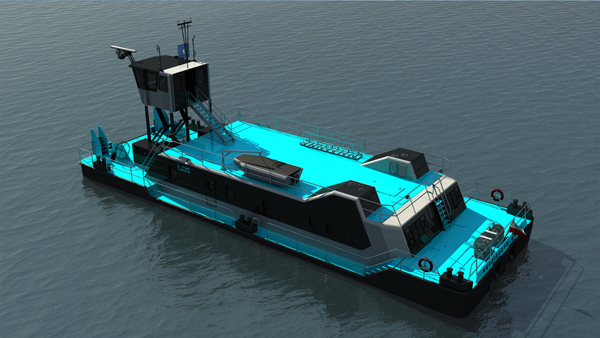

The interior of the pusher is largely made up of the engine room and lower rooms ensuring comfortable work and rest for the three crew. Two symmetrical cabins closer to the stern are equipped with beds, desks and wardrobes for personal items. The cabins are connected by a shared bathroom with toilet. The corridor leads to exits on both sides of the ship and to all crew quarters. Closer to the bow is the captain's cabin, which is larger than the other two and has a separate bathroom. Pentra (kitchen) is a meeting place and conducive to shared meals. Therefore, in addition to the kitchen equipment, it is also important to sit comfortably and watch TV. The lifted wheelhouse can only be accessed from outside the ship. It is possible from the side in the lowered position. Access to the lifted wheelhouse is possible after climbing the roof of the superstructure and climbing the stairs leading to the rear door.

INTERIOR PLAN

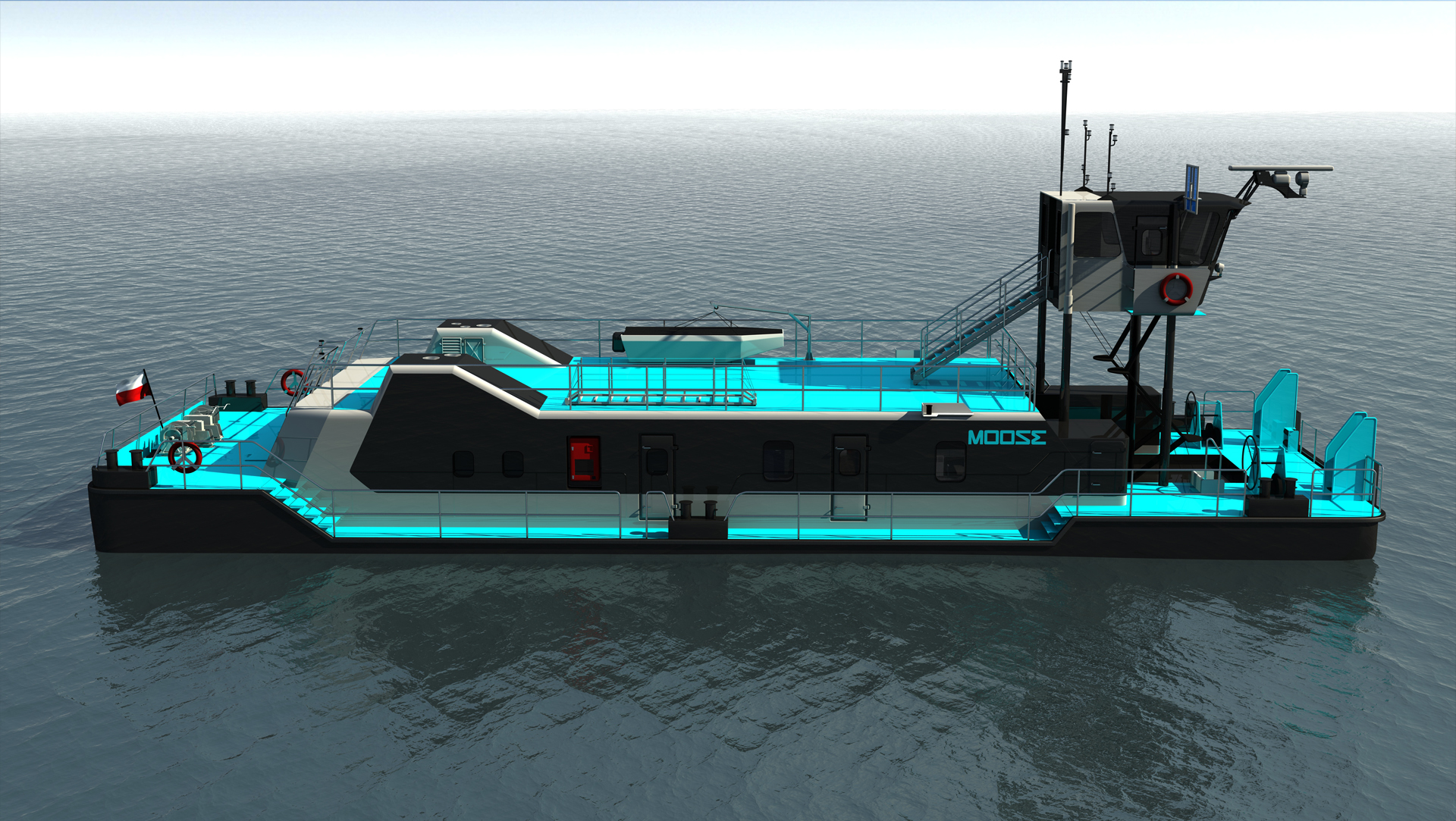

Inland pusher for work in a set with a barge or a pontoon with a capacity of 100 to 400 tons, on which various loads, including large-size ones, can be transported with the pusher's draft of 0.6 m. The pusher's task will be to ensure transport on the route from Brzeg Dolny to Szczecin with minimal water levels in the Odra River. The navigation equipment will enable round-the-clock navigation. The pusher will be made as a three-screw flat-bottomed vessel with a superstructure and a raised wheelhouse in the bow area. Three propulsion systems with three propellers working in the nozzles and three coupled rudders will ensure great maneuverability. The wheelhouse will be raised and lowered by a hydraulically driven mechanism. The living and sanitary rooms for the crew (three people) will be located in the superstructure directly behind the wheelhouse with access from the deck to the LB and RB. The maximum height of the fixed structure will be 4.4 m above the base plane. All items protruding above this height will be folded. The hull will be made of high-strength steel, while the deckhouse and wheelhouse will be made of aluminum alloys.

©2021 - WWDESIGN.EU